CNC Shearing

copy.jpg)

Standard Feature Accessries

• Moving beam Synchronized by differential cylinders

• hardened rollers guide beam for constant blade gap.

• Blade gap easily adjustable by calibrated levers.

• Rake angle sdjustable to suit thikness and material.

• Activation from consol and movable foot switch.

• Sheet clamped Hydraucally before cut starts.

• Stroke length - position can be set for short jobs.

• Beam returns on releasing foot switch for smaler cuts.

• First two hold downs spaced closer at both ends.

• Squaring arm 1000mm at left with hardened liners.

• Squaring arm 600mm at right helps distribute wear.

• Two front supports for supporting longer plates.

• Front operater mitorized back gauge 1000mm travel with D.R.O

• Coppact, Low maintenance of silent Hydraulic system.

Feature

• Mono Block Welded Steel ridid to deflection tensile Moment of high tensille.

• Easy of accurate gap adjustment of blades for bur-free cuts.

• Monorized back gauge with electronic digital readout.

• Electronically adjustment RAKE ANGLE as per material of thickness for twist free cuts.

• Synchronized Beam guided system for constant gap between Blades.

• Extra capacity to cut Hard-thicker plate than nominal capacity.

• Blades Produced from High alloying steel with functionalfour side.

• Adjustable Cutting & clamping force for quality cutting & power saving,

• Rapid cutting of short pieces by electrical stroke adjustment system.

- CNC Machinery

- CNC Press Brake

- CNC Shear

- CNC Plate Punching

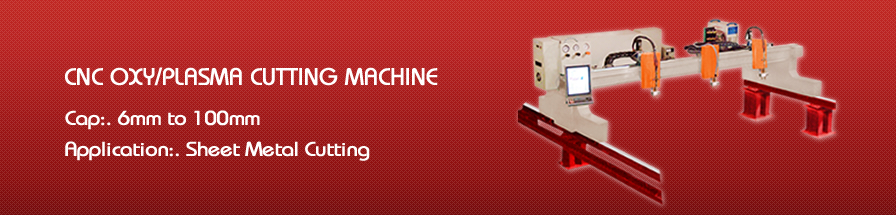

- CNC Plasma Cutting

- CNC Waterjet

- CNC Router

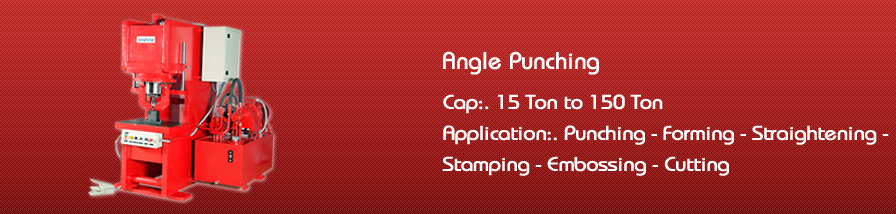

- CNC Angle Punching

- Hydraulic Machinery

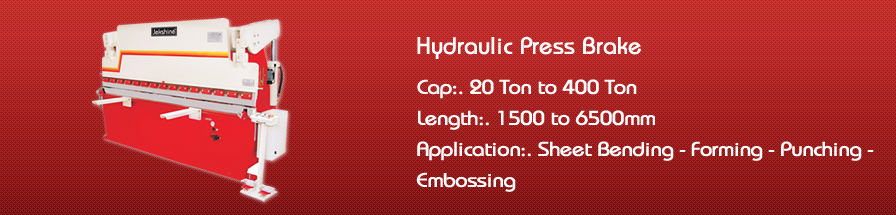

- Hyd.Press Brake

- Hyd.Shear

- Hyd.C Type Press

- Hyd.Press

- Transmission Tower Making Machinery

- Angle Shearing Machine

- Angle Punching Machine

- Angle Stamping Machine

- Angle Knotching Machine

- Hyd.Press Brake

- Special Purpose Machinery

- CNC Extra Long Milling

- Material Handling System

- Embossing Machine

- Bellow Manufacturing Machines

- Welding Fixtures

- Positioner & Turn Table

- And More...